ΔE2 - The Next Evolution of ΔE®

ΔE2 is an easy to use system that utilises data from drills or other sources that characterise rock properties to allow targeted placement of energy in the blast hole.

The Next Evolution of ΔE

Optimised Energy Placement

ΔE2 is an easy to use system that utilises data from drills or other sources that characterise rock properties to allow targeted placement of energy in the blast hole.

ΔE2 allows mine blasting load plans to be sent directly to the loading equipment to help ensure boreholes are loaded as designed.

ΔE2 allows mine blasting load plans to be sent directly to the loading equipment to help ensure boreholes are loaded as designed.

Features

- Easily integrated into any DYNOBULK® ΔE® Mobile Processing Unit (MPU).

- Captures accurate information about the loading of each hole in the shot

- Allows explosives energy to be accurately placed where needed in the blast hole

- Allows fine tuning of powder factors for the shot or even individual holes in a shot

- Loading profile feature allows custom loading plans to be reused

Benefits

- Improves operator efficiency by simplifying the loading process

- Accurate information captured can be used as part of the shot reporting process

- Accurately placed energy can reduce oversize and/or fines as required

- Gives control of the loading process back to the engineer or shotfirer through easy to use software that sends loading instructions directly to the loading equipment

- Loading profiles allow a specific loading scenario to be created and used many times to speed up design

Software Design

The Preload software has many different tools:

• Drawing tools that allow the addition of lines, circles, and squares

• Text can be added to the shot

• Annotations can be made

• Arrows can be drawn

• Reports can be printed for users and MPU operators to have hard copies of the loading plan in the field

• Customised hole loading plans can be created and the information can be sent to the MPU to allow precise control over how holes are loaded within the shot.

• Drawing tools that allow the addition of lines, circles, and squares

• Text can be added to the shot

• Annotations can be made

• Arrows can be drawn

• Reports can be printed for users and MPU operators to have hard copies of the loading plan in the field

• Customised hole loading plans can be created and the information can be sent to the MPU to allow precise control over how holes are loaded within the shot.

Data

Importing Data:

Data can be imported from a variety of sources:

• CSV.

• XML.

• Excel files

• Directly from customer databases

• Smart drills

• Normal shot plans without smart drill data

• Dyno Nobel mobile applications that create shot designs

Utilising Data:

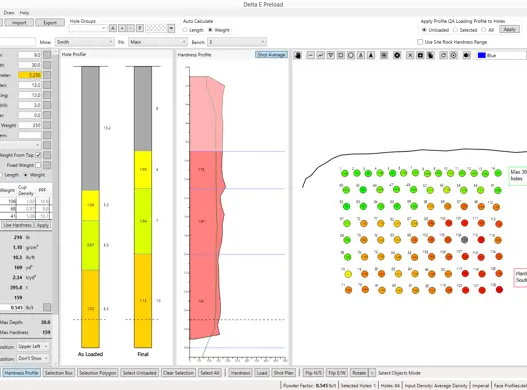

• Through the use of colours, the user can utilise drill data and drill hardness data, analyze and view rock hardness profiles

• Ex) red material is harder than green material

• Through a single button click and a hole profile look-up, the shotfirer can load the entire shot based on rock hardness

• Different densities can be applied to each borehole and segments within a borehole

• Up to six different densities can be loaded in any given borehole

• Face profile data can be used to automatically determine densities for face holes.

Exporting Data:

• Loading data exported from the program is sent to the DynoLogix® control system, to load the bore hole.

Data can be imported from a variety of sources:

• CSV.

• XML.

• Excel files

• Directly from customer databases

• Smart drills

• Normal shot plans without smart drill data

• Dyno Nobel mobile applications that create shot designs

Utilising Data:

• Through the use of colours, the user can utilise drill data and drill hardness data, analyze and view rock hardness profiles

• Ex) red material is harder than green material

• Through a single button click and a hole profile look-up, the shotfirer can load the entire shot based on rock hardness

• Different densities can be applied to each borehole and segments within a borehole

• Up to six different densities can be loaded in any given borehole

• Face profile data can be used to automatically determine densities for face holes.

Exporting Data:

• Loading data exported from the program is sent to the DynoLogix® control system, to load the bore hole.

Reporting

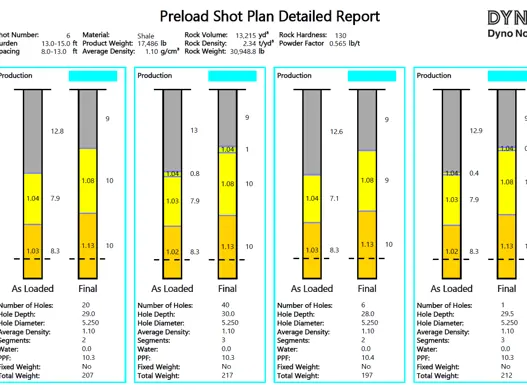

Once this information is created, reports are available that will allow the user to see:

• How the holes will be loaded

• What the actual hole loads will look like in the shot with each density

• Statistics around that information.

Shot plans are available that give powder factors, rock volume shot, rock hardness as an overall average for the shot, and again color coding.

• How the holes will be loaded

• What the actual hole loads will look like in the shot with each density

• Statistics around that information.

Shot plans are available that give powder factors, rock volume shot, rock hardness as an overall average for the shot, and again color coding.